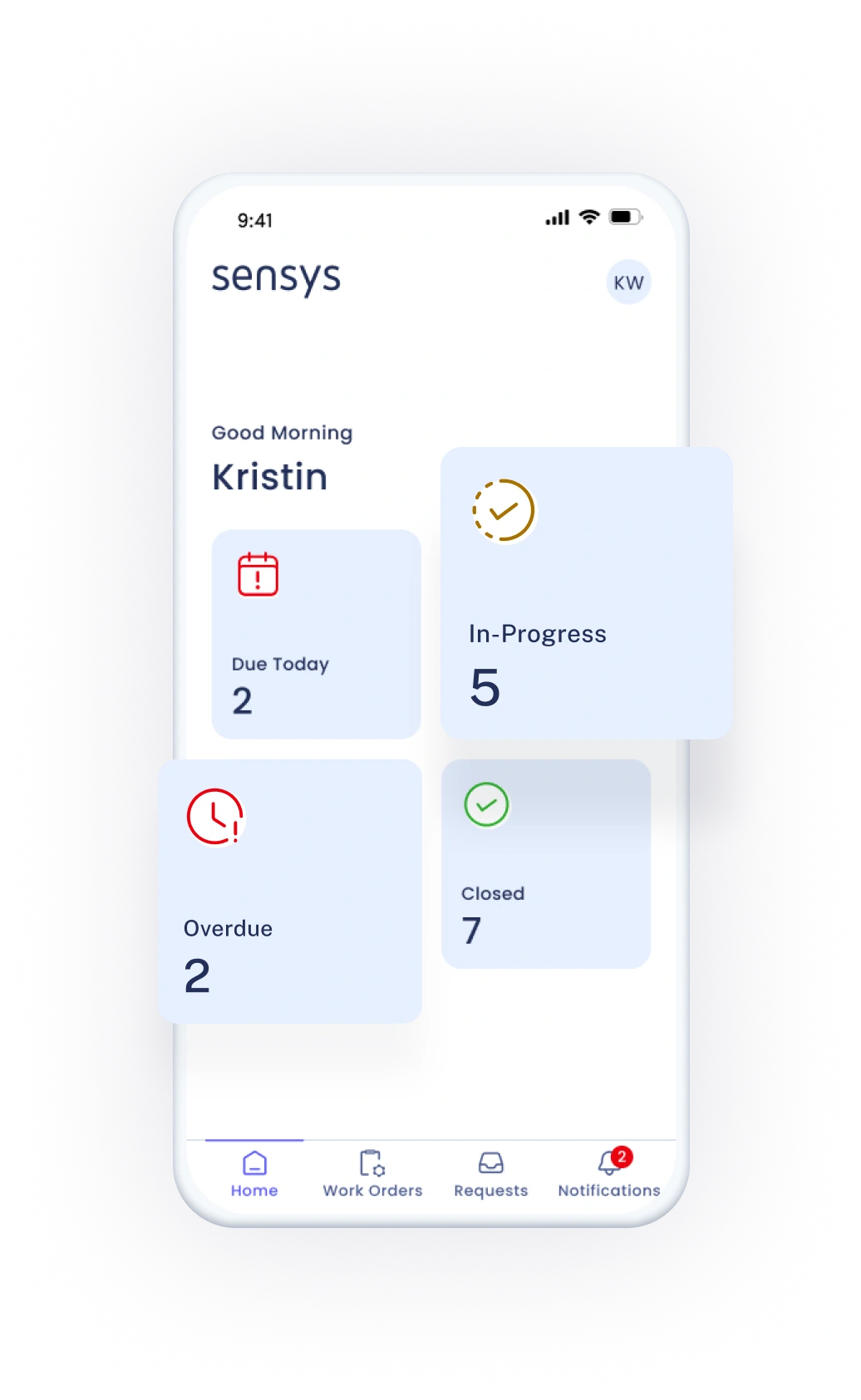

Maintenance Operations

made easy.

Most maintenance software forces you to sacrifice feature richness for ease of use. Sensys gives you both, providing a wonderful user experience for both simple and complex activities.

Maintenance Operations made easy.

Most maintenance software forces you to sacrifice feature richness for ease of use. Sensys gives you both, providing a wonderful user experience for both simple and complex activities.

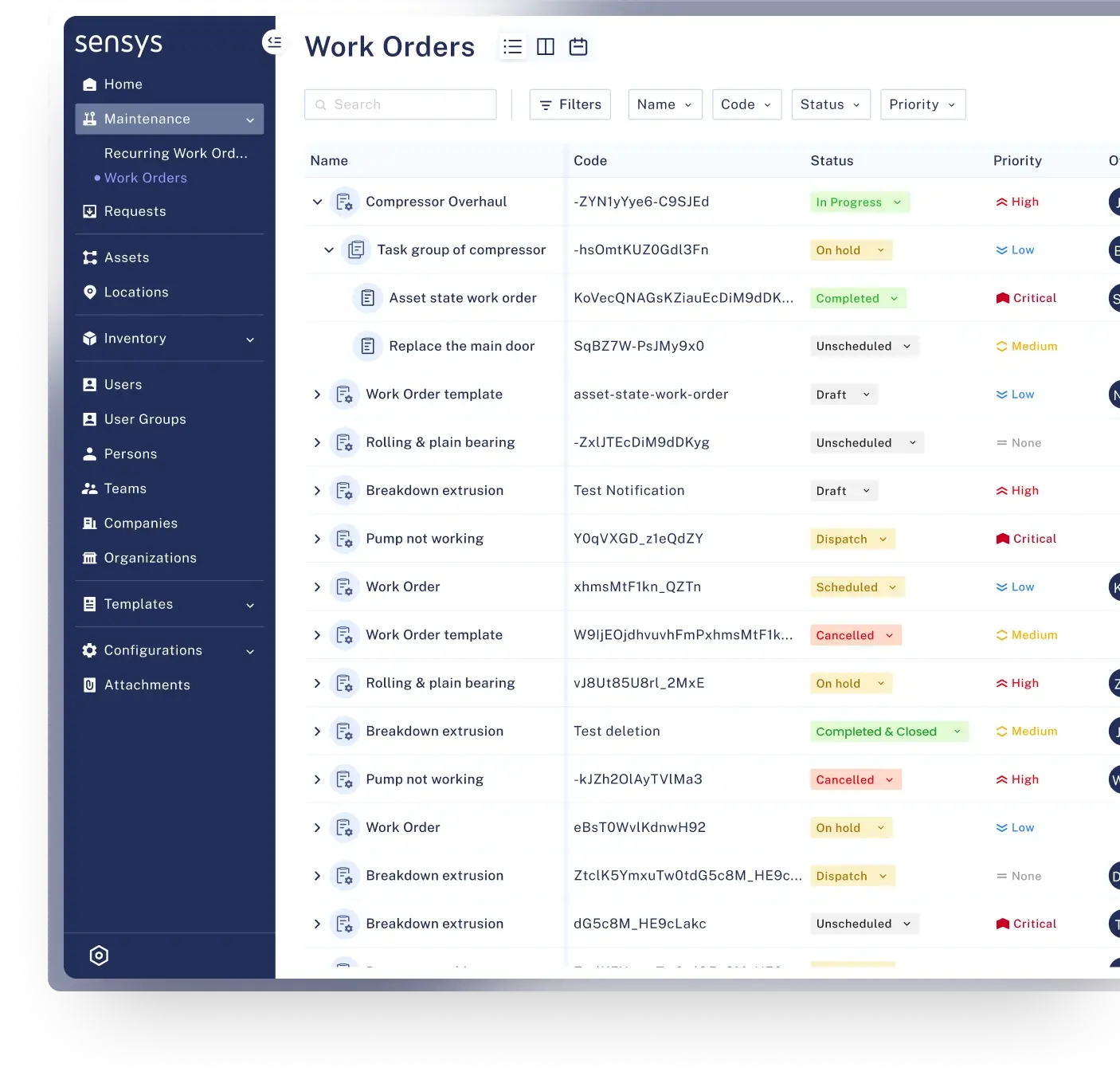

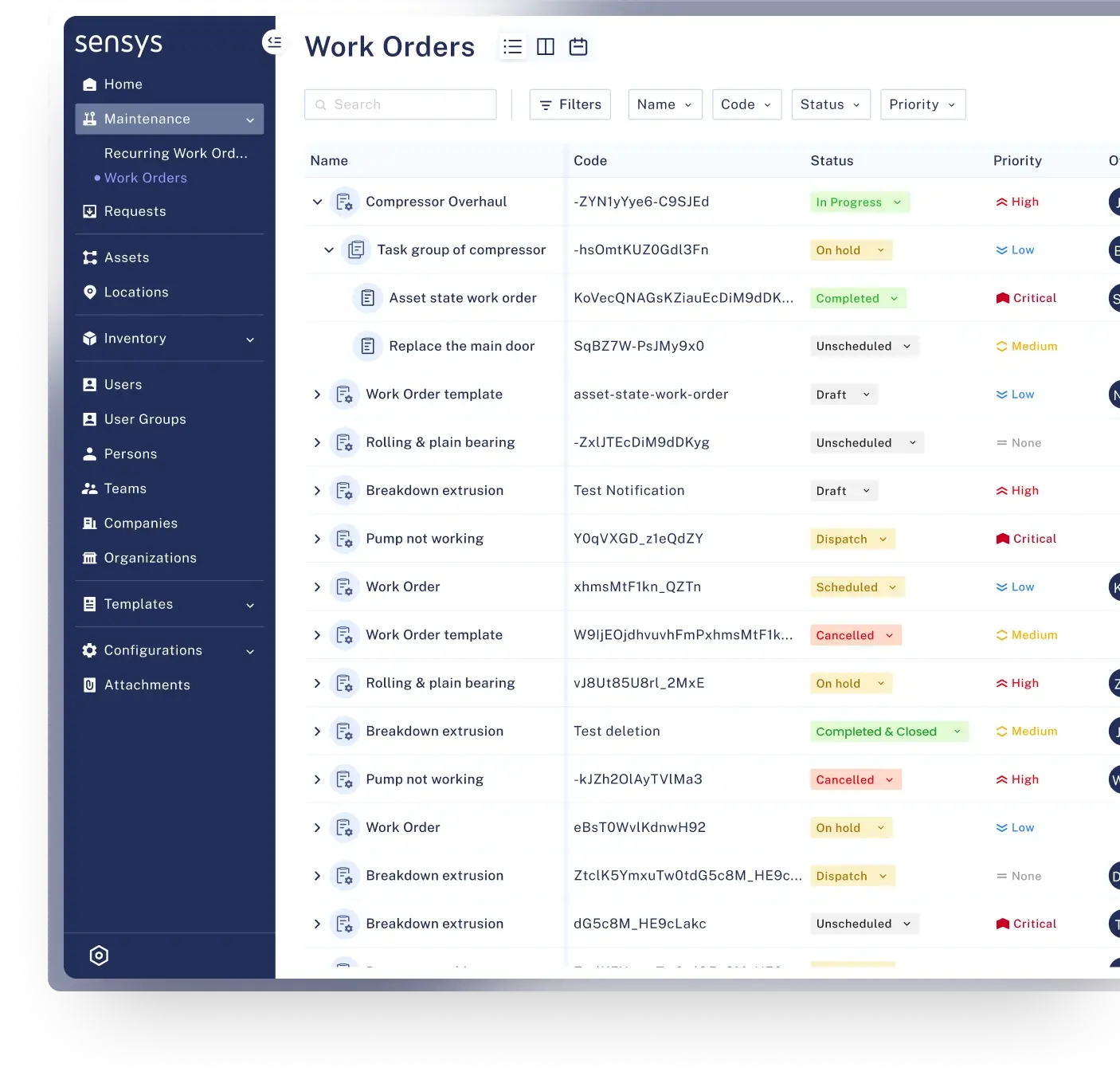

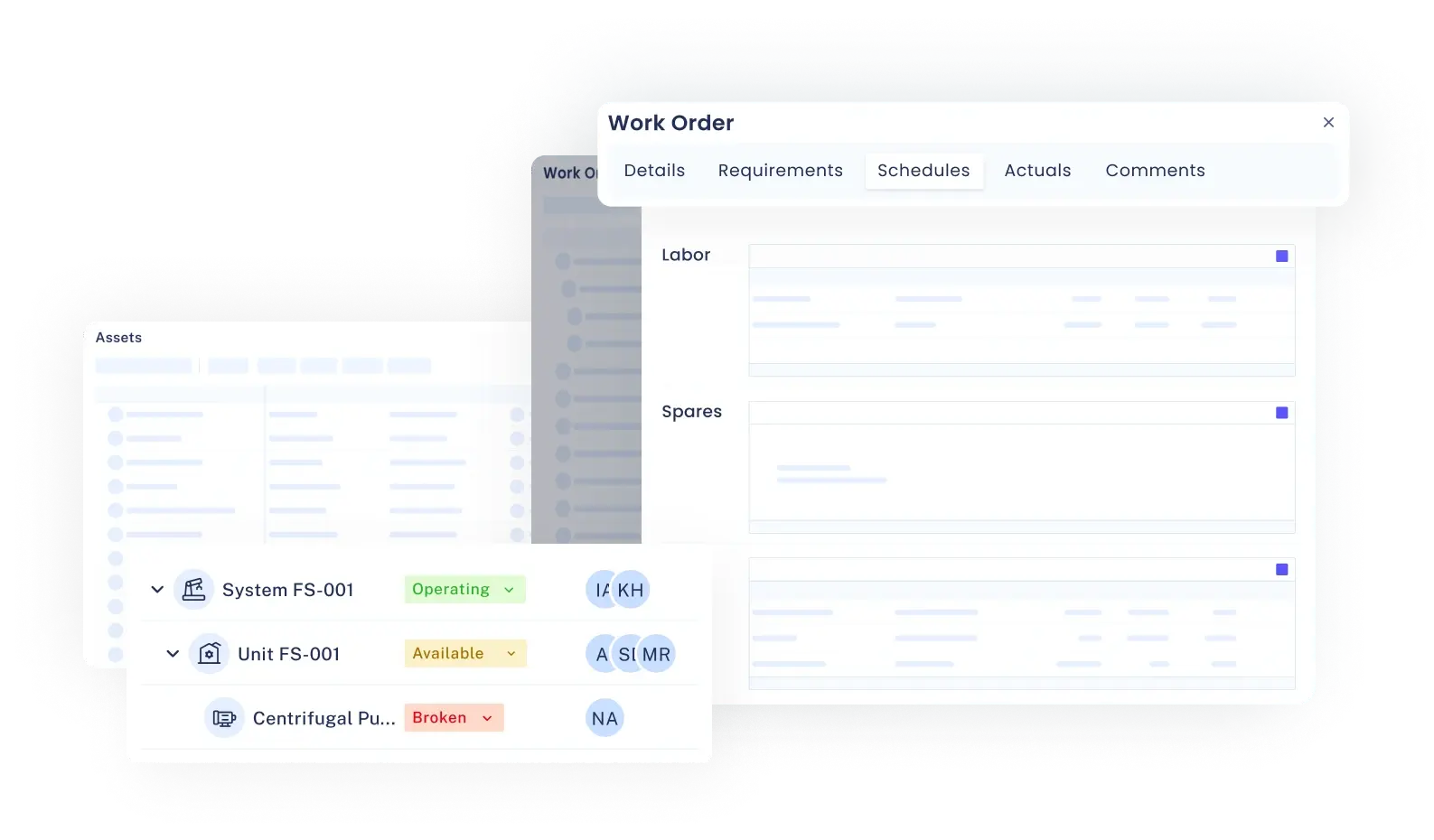

Powerful and easy Work Order, Asset, and Resource Management.

Capture all the data and information you need through an end-to-end work order management process. Prioritize work, assign and schedule resources, and review it all from a best-in-class grid interface.

Features

- Initiate work orders on both Assets (equipment, tools, vehicles) and Locations.

- Assign resources including individuals, teams, tools, and vehicles to any work order.

- Categorize and prioritize your work.

- Link spares directly to Assets to combine inventory and work order management.

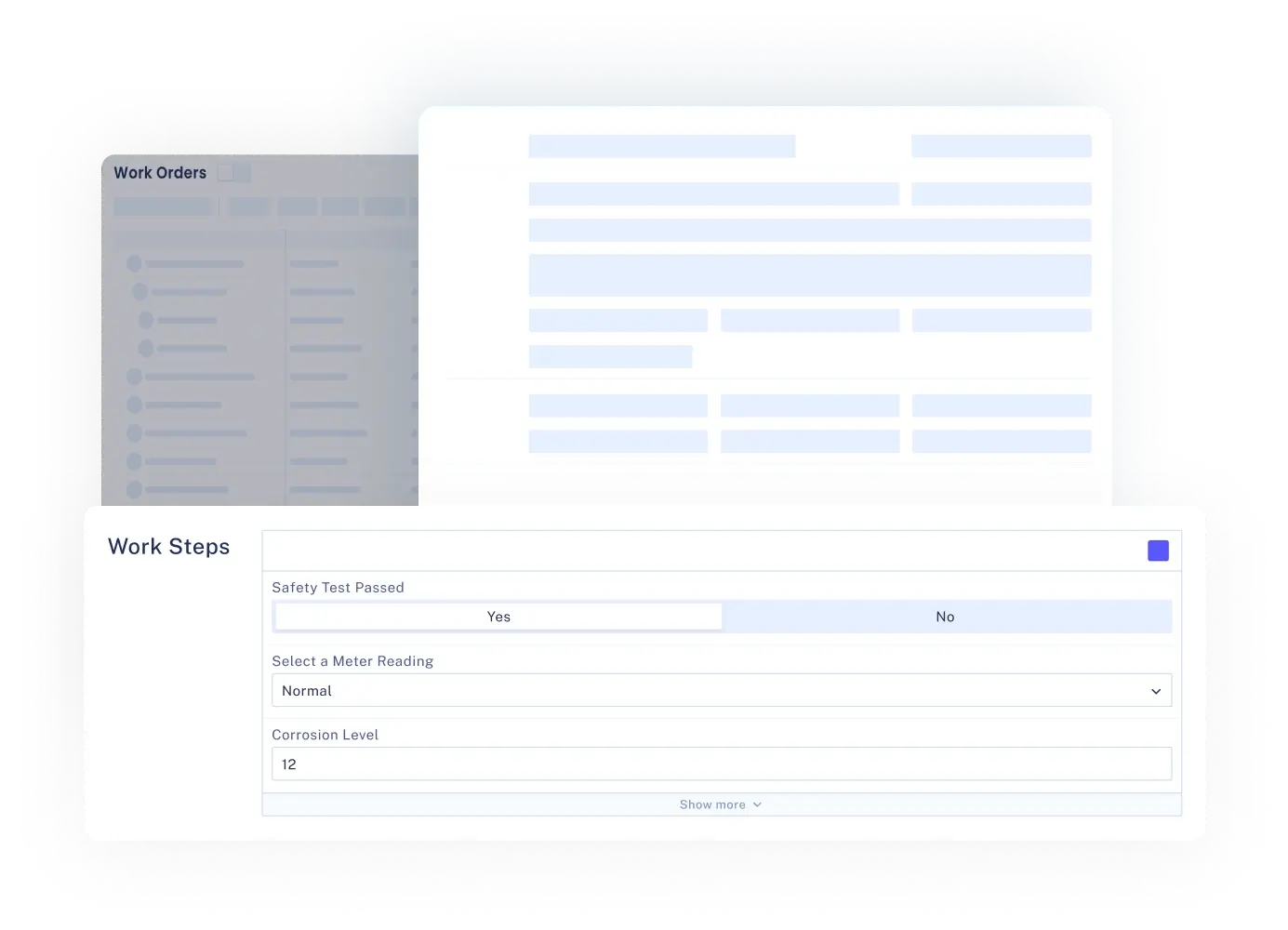

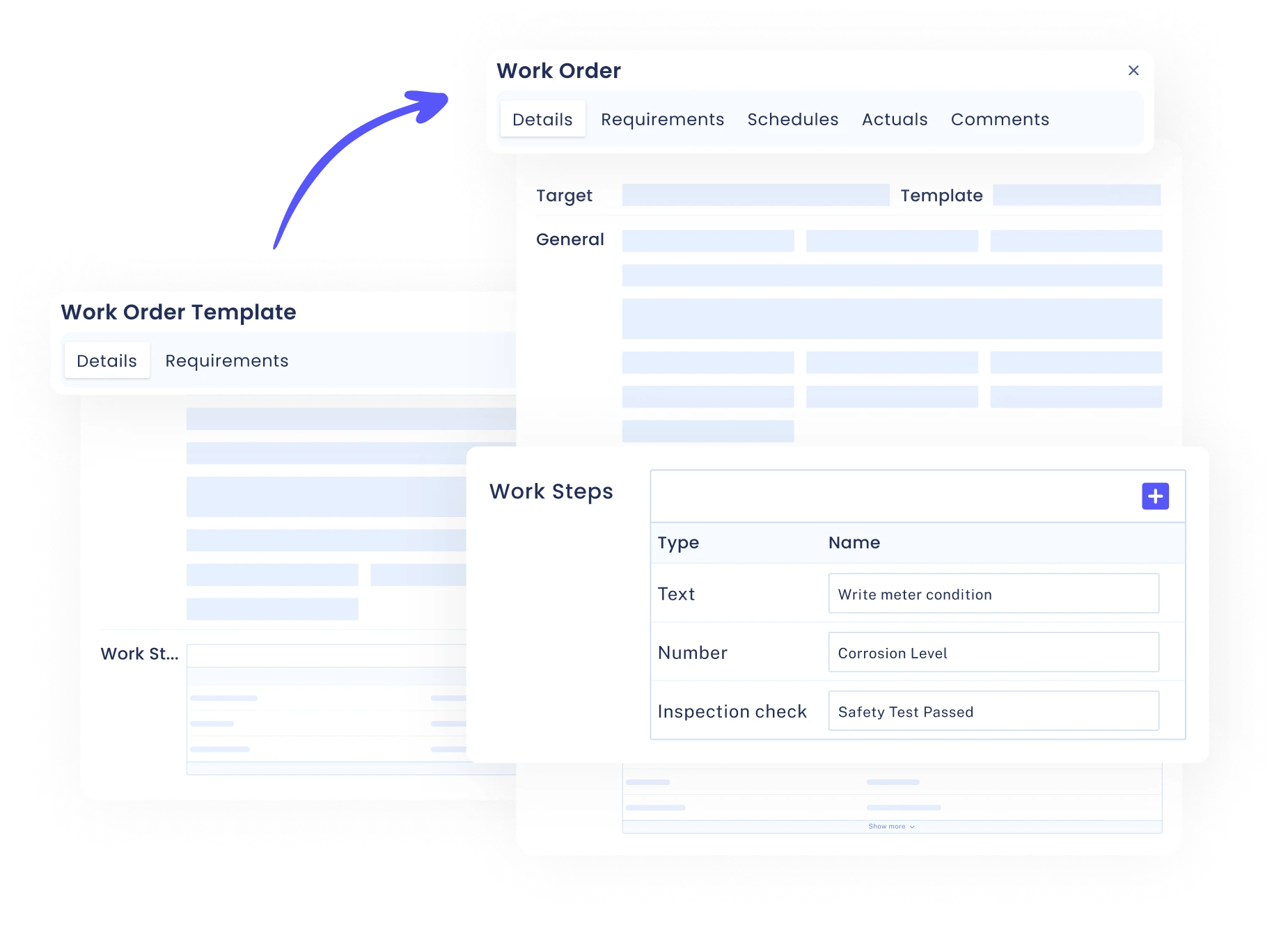

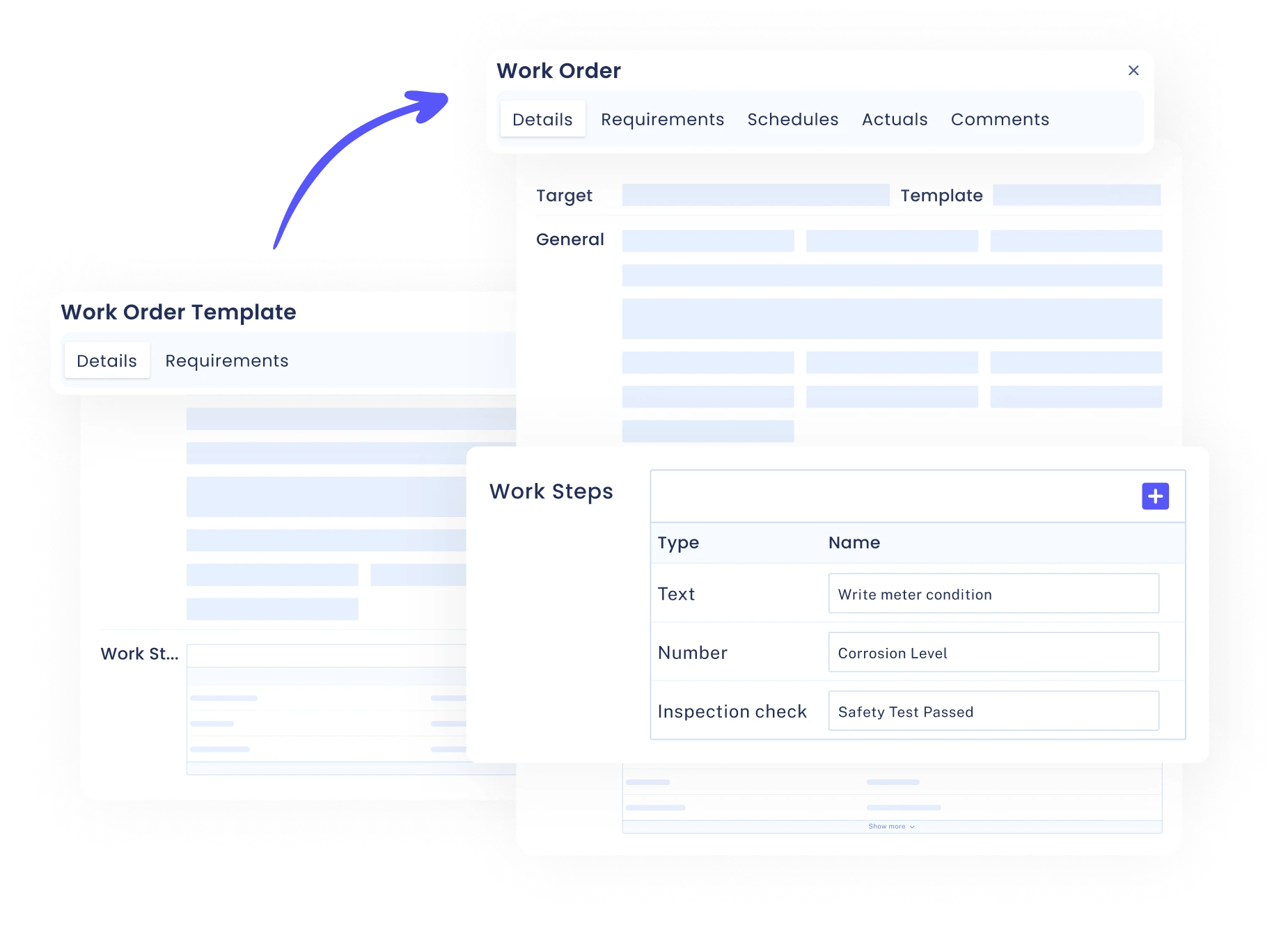

Use Work Steps to ensure repeatability and capture field data.

Most maintenance activity involves multiple steps that must be done in a specific order to achieve success. Sensys allows you to easily capture these through Work Steps under any Work Order. This allows your field teams to focus on execution without wondering what needs to be done next. It also provides a valuable tool for continuous training and improvement.

Features

- Create Work Steps under any Work Order or Task.

- Choose from options including text entry, number entry, and dropdown lists.

- Make it easy for field personnel to follow best practices and procedures.

- Achieve quick on-the-job training and prepare your teams for success.

- Capture data from inspections or operator rounds.

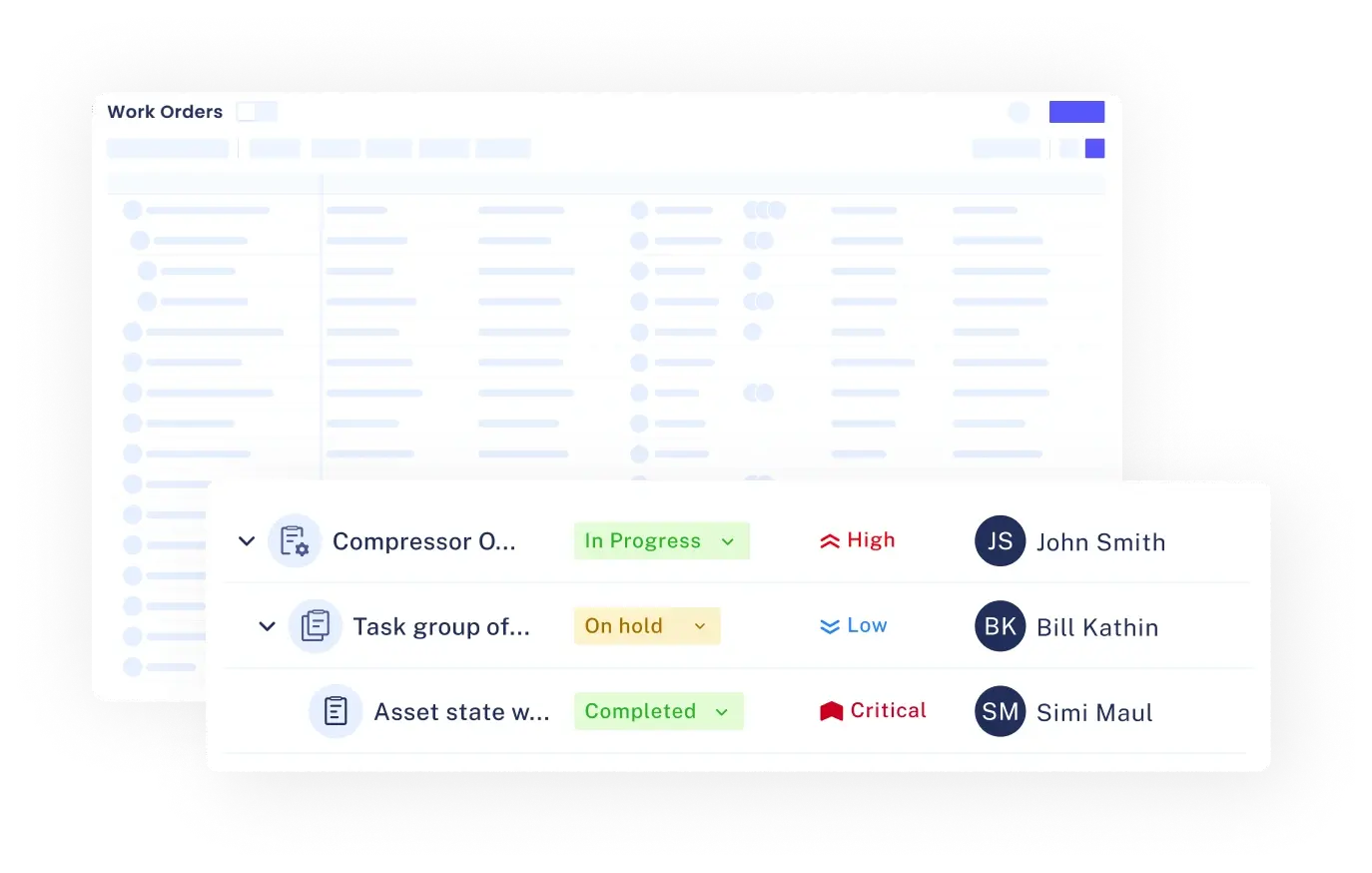

Efficiently manage complex maintenance using Task Groups.

All work orders are not created equal; some are simple, others quite complex. With Sensys, you can manage this complexity by combining Work Orders with Task Groups and Tasks.

Features

- Combine Tasks into Task Groups for exceptional activity planning.

- Make complex activities like overhauls or turnarounds easier for your teams.

- Use Task Groups with Templates to digitally capture advanced maintenance procedures.

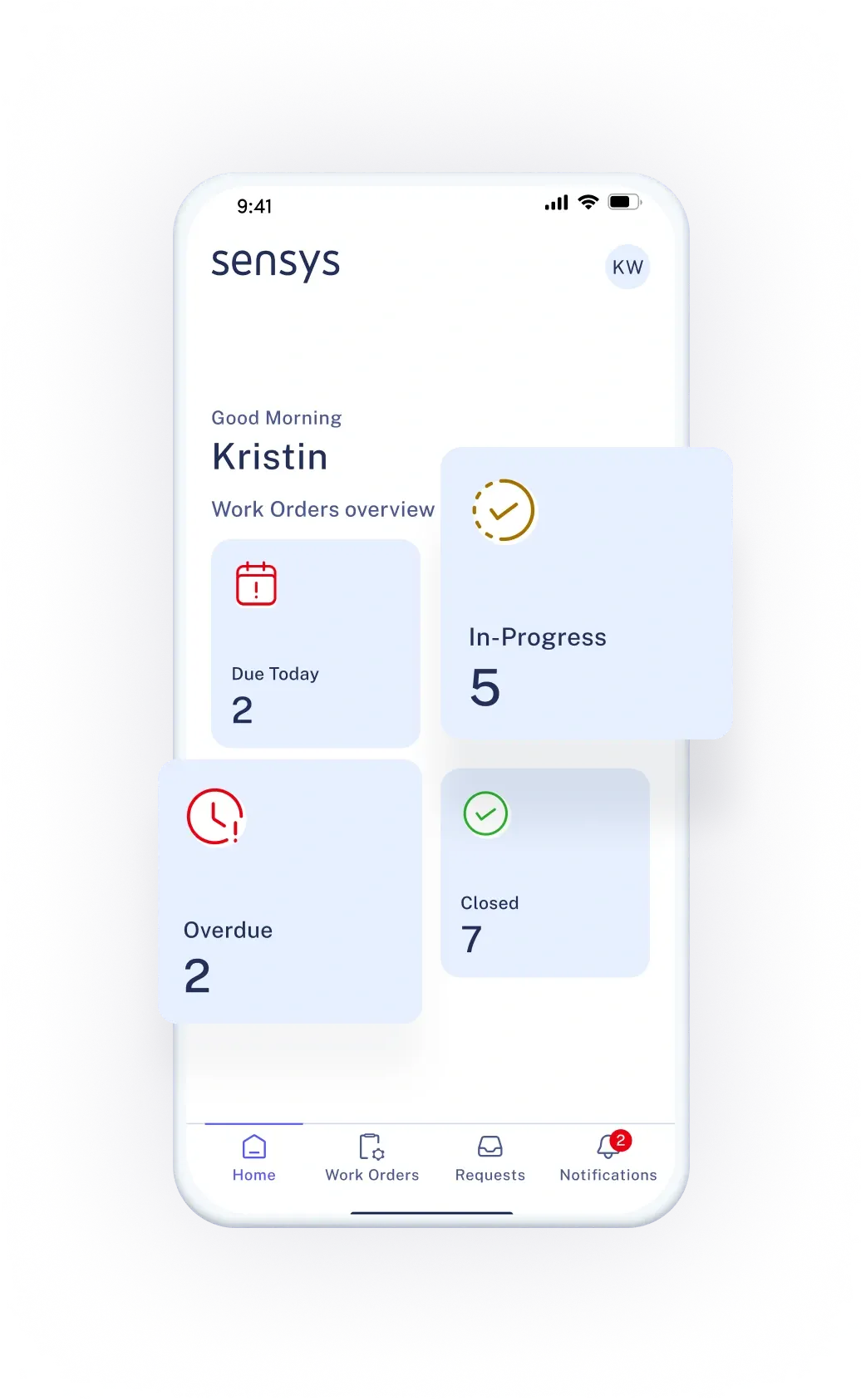

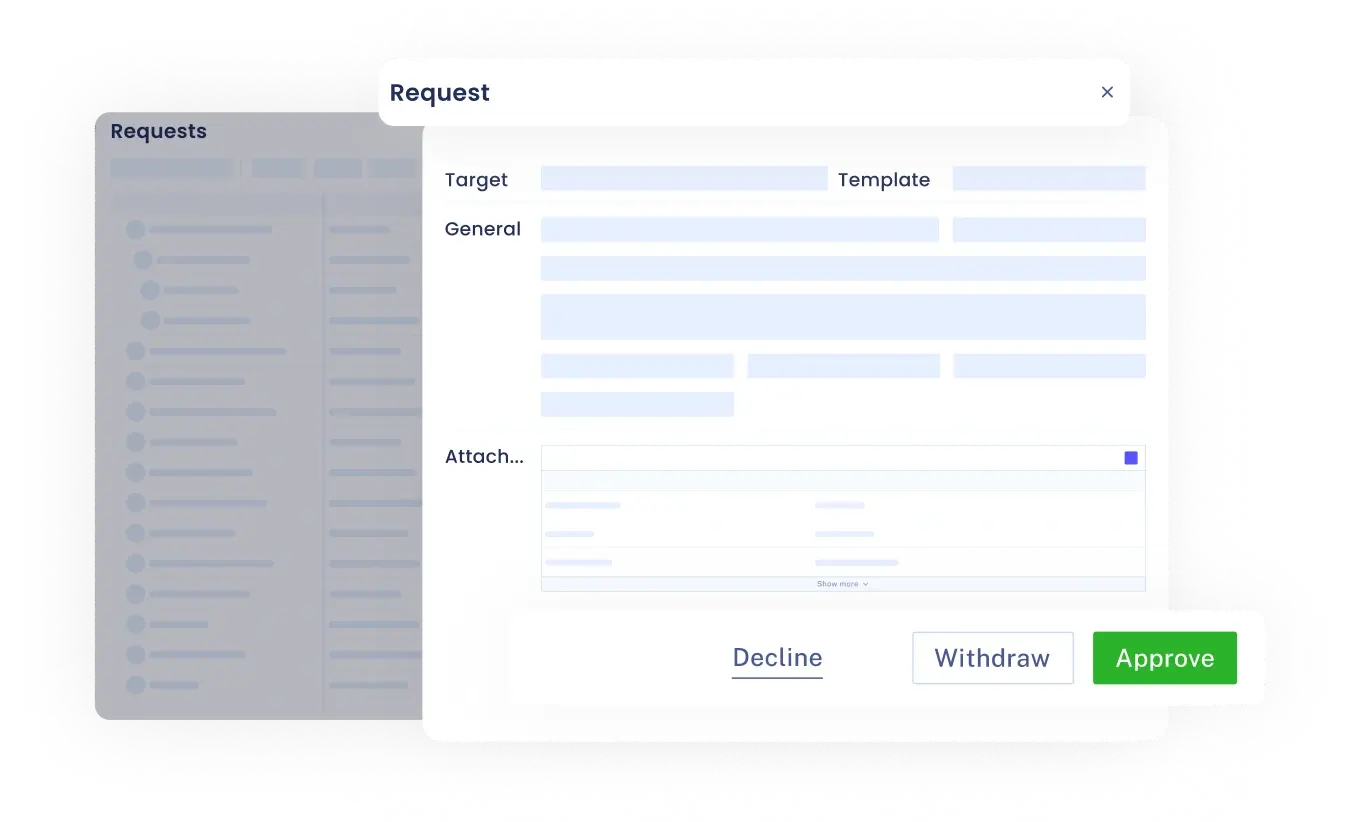

Capture requests from across your organization.

Allow any member of your organization to create a Request, even if they aren’t part of your core maintenance team. A Request is an optional part of the service workflow, so users can skip it and go straight to creating a work order.

Features

- Allow any user to create service requests.

- Authorized users can approve Requests, which then create Work Orders.

- Generate Requests through Sensys Mobile, enabling better field inspections.

- Coming soon: A request portal for users outside your organization.

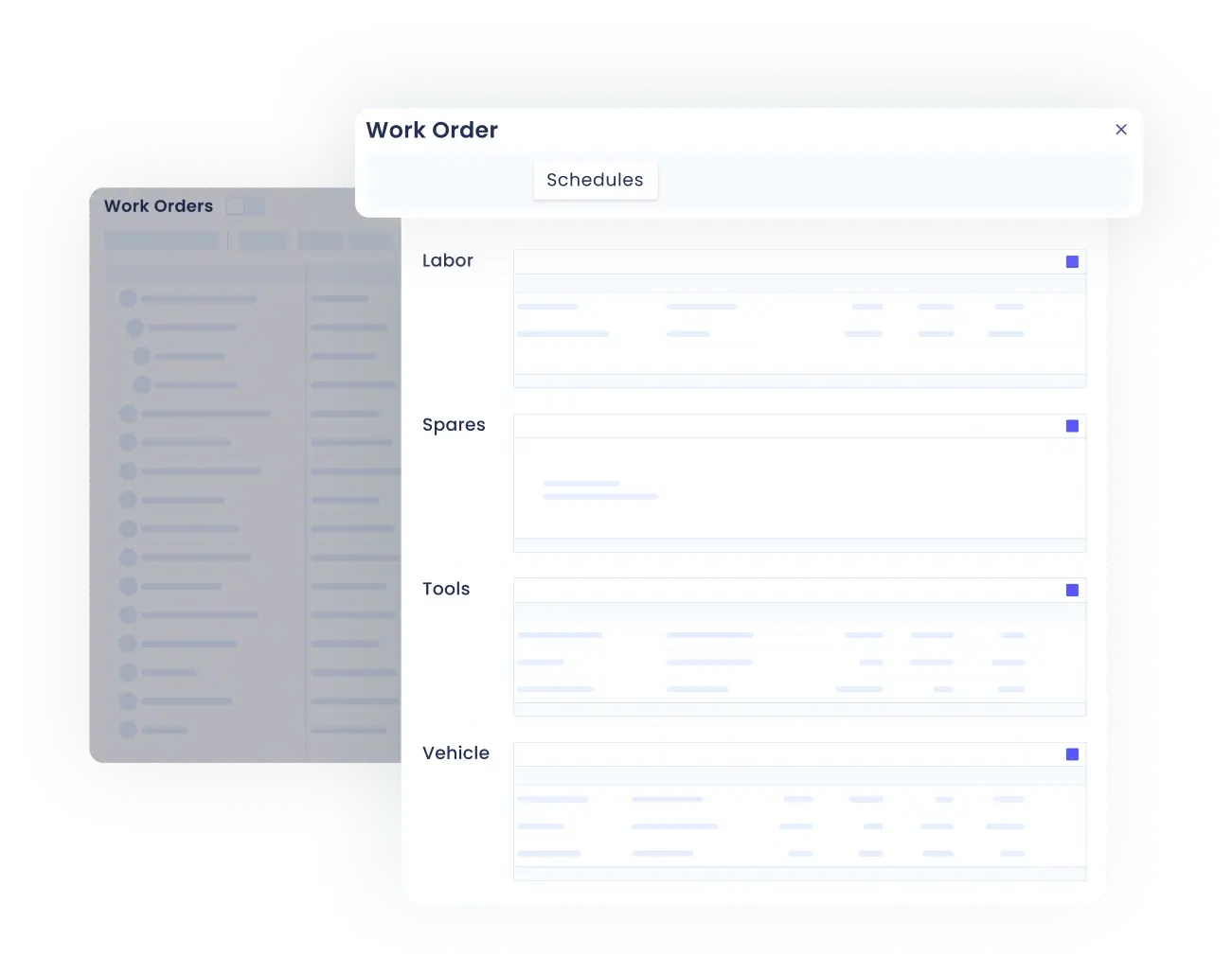

Plan, Schedule, and Dispatch resources.

Maintenance organizations face the challenge of balancing demand with the supply of people, spares, and tools. Sensys allows you to schedule any resource, including individual skills, so that you can plan your maintenance activities well in advance and get ahead of demand.

Features

- Schedule any resource - people, skills, spares, tools, and vehicles.

- Scheduling a skill lets you capture the requirement without assigning a specific individual.

- Improve planning by identifying last-minute scheduling changes.

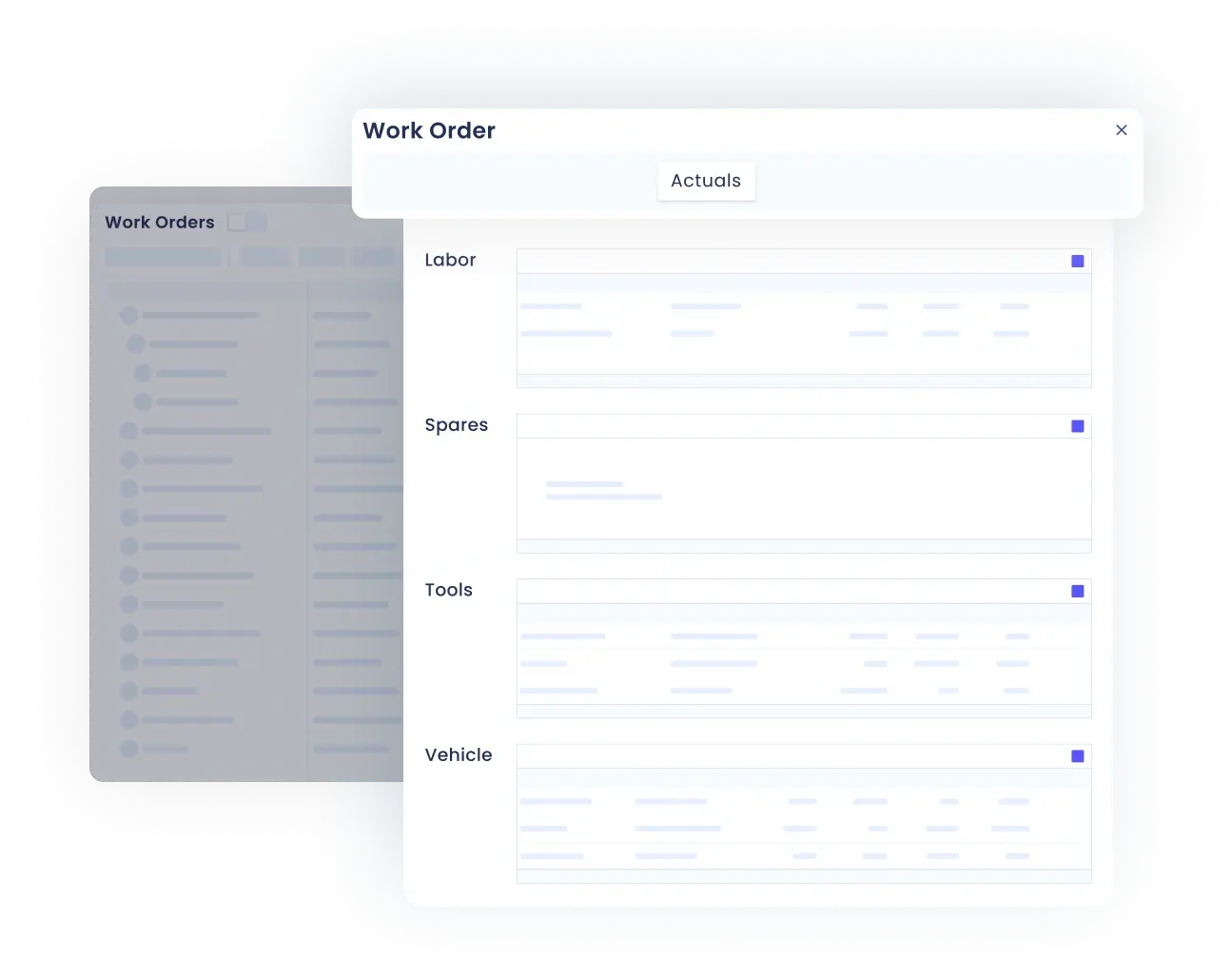

Track time and costs.

Efficient maintenance programs minimize the time and cost spent on activities. This starts with capturing time and cost data, which Sensys allows you to do at the individual resource level.

Features

- Track time and cost - both estimates and actuals - for persons, tools, and vehicles.

- Get additional insight through spend analytics and dashboards.

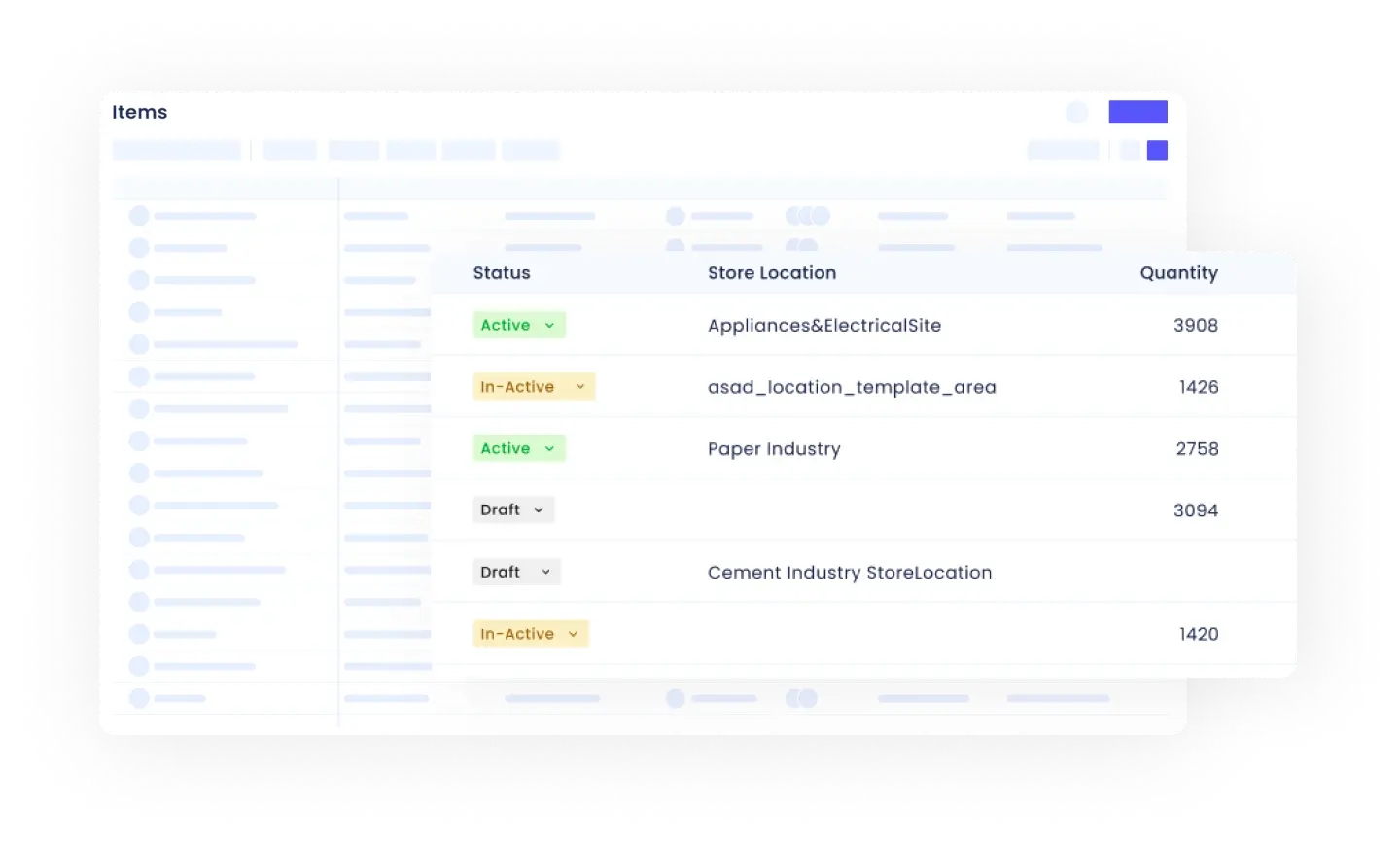

Simple and straightforward Inventory Management.

All maintenance organizations require spare parts, tools, and vehicles to successfully execute their work. Tracking these resources and ensuring they are available for maintenance activities is crucial for long term success. Sensys’ Inventory module offers a simple and intuitive set of features that work in tandem with Work Orders.

Features

- Create virtual Inventory Stores that can be associated with physical Locations.

- Define an unlimited number of Items and track their location, price, and suppliers.

- Reserve and assign inventory resources to any work order.

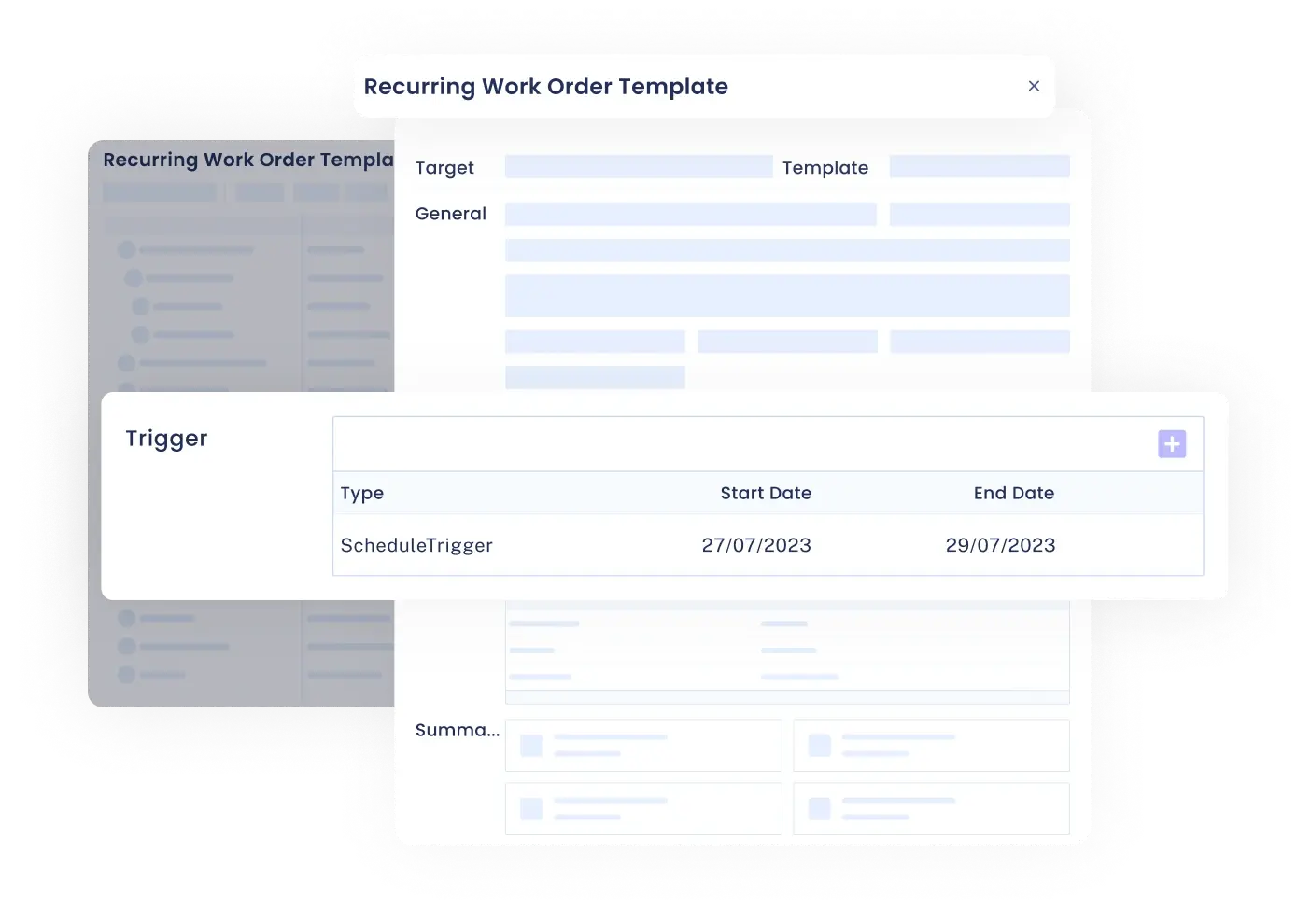

Run a great Preventive Maintenance program.

Effective PM programs help maximize uptime. Keeping track of these programs and their schedules can be challenging if you have a lot of assets, locations, or members in your team. Sensys lets you digitize your PM program by automatically scheduling work orders on a predefined schedule.

Features

- Schedule work orders based on time triggers just like a calendar invite.

- Choose any day of the week and repeat daily, weekly, or monthly.

- Minimize the chance of your team forgetting to schedule maintenance on time.

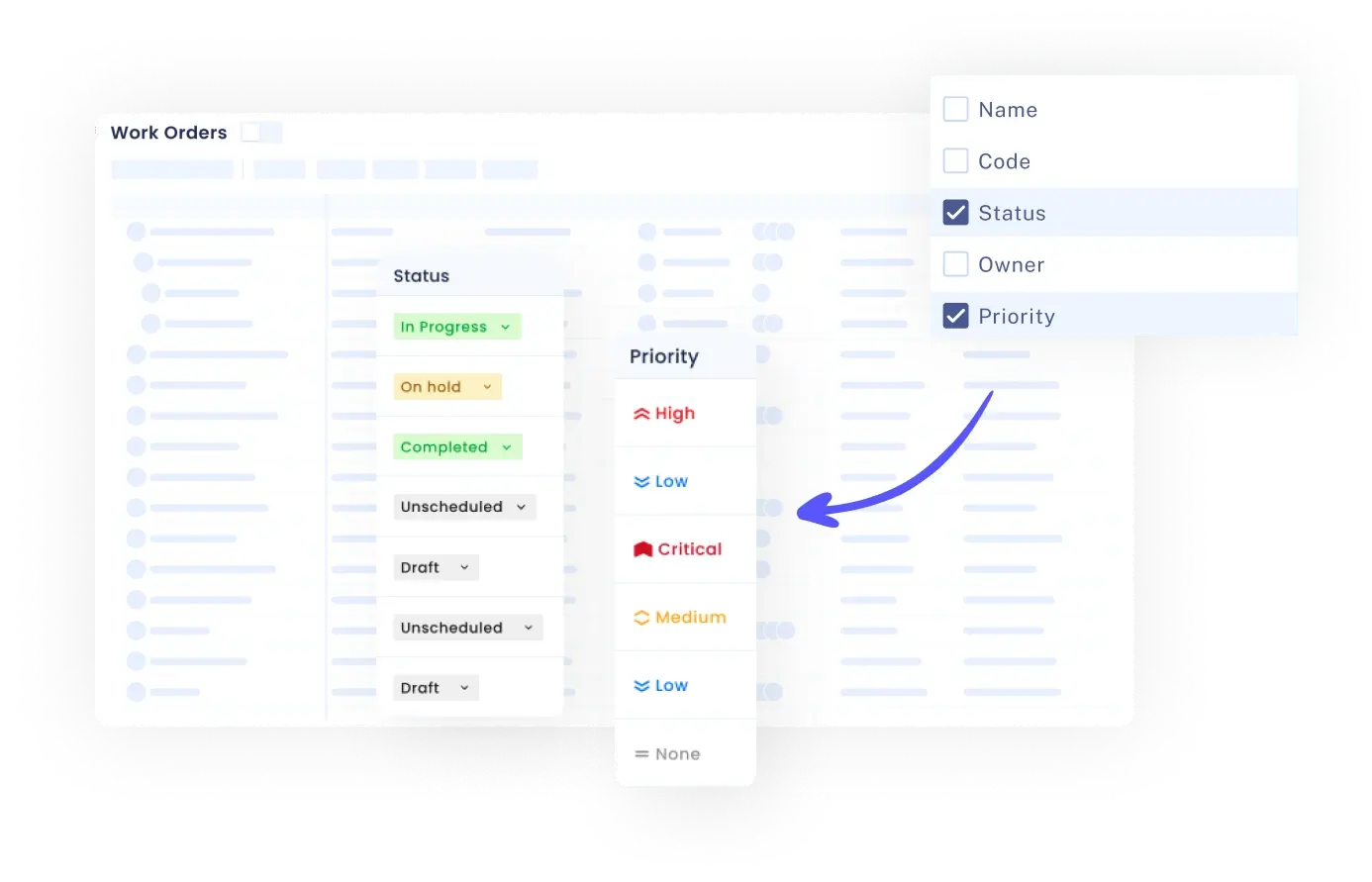

Save time and clicks with our flexible grid view.

Planners, dispatchers, and supervisors have a lot of information to process. They may be dealing with tens of work orders every day while trying to keep track of different parameters like status and resource assignments. Sensys’ Operations grid gives users the power to view every work order’s end-to-end plan from one view.

Features

- Customize your grid through column selection, including custom properties.

- Update Statuses directly in the grid without having to switch views.

- Interact with Work Orders, Task Groups, and Tasks directly from the grid.

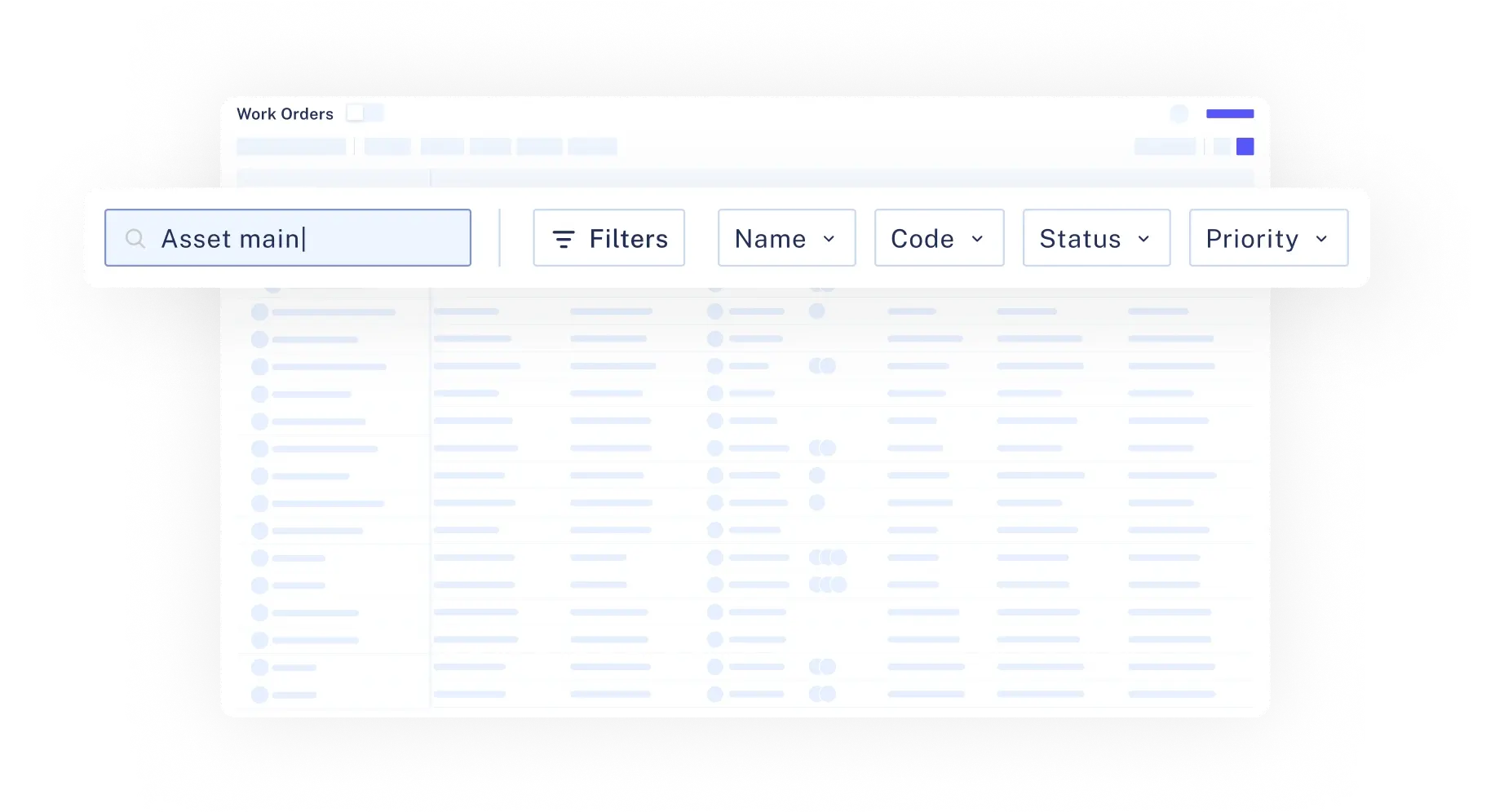

Filter and search like a pro.

Quickly finding what you’re looking for in a growing realm of digital data can be quite a challenge. To make things easy and efficient, we’ve developed powerful features that let you search and filter across a wide array of dimensions. Want to see all the work orders in which a particular vehicle has been used? No problem. Searching for those work orders in which you need a particular skill like welding? We have you covered.

Features

- Search and filter across 30+ dimensions including custom properties.

- Save filters for operational efficiency.

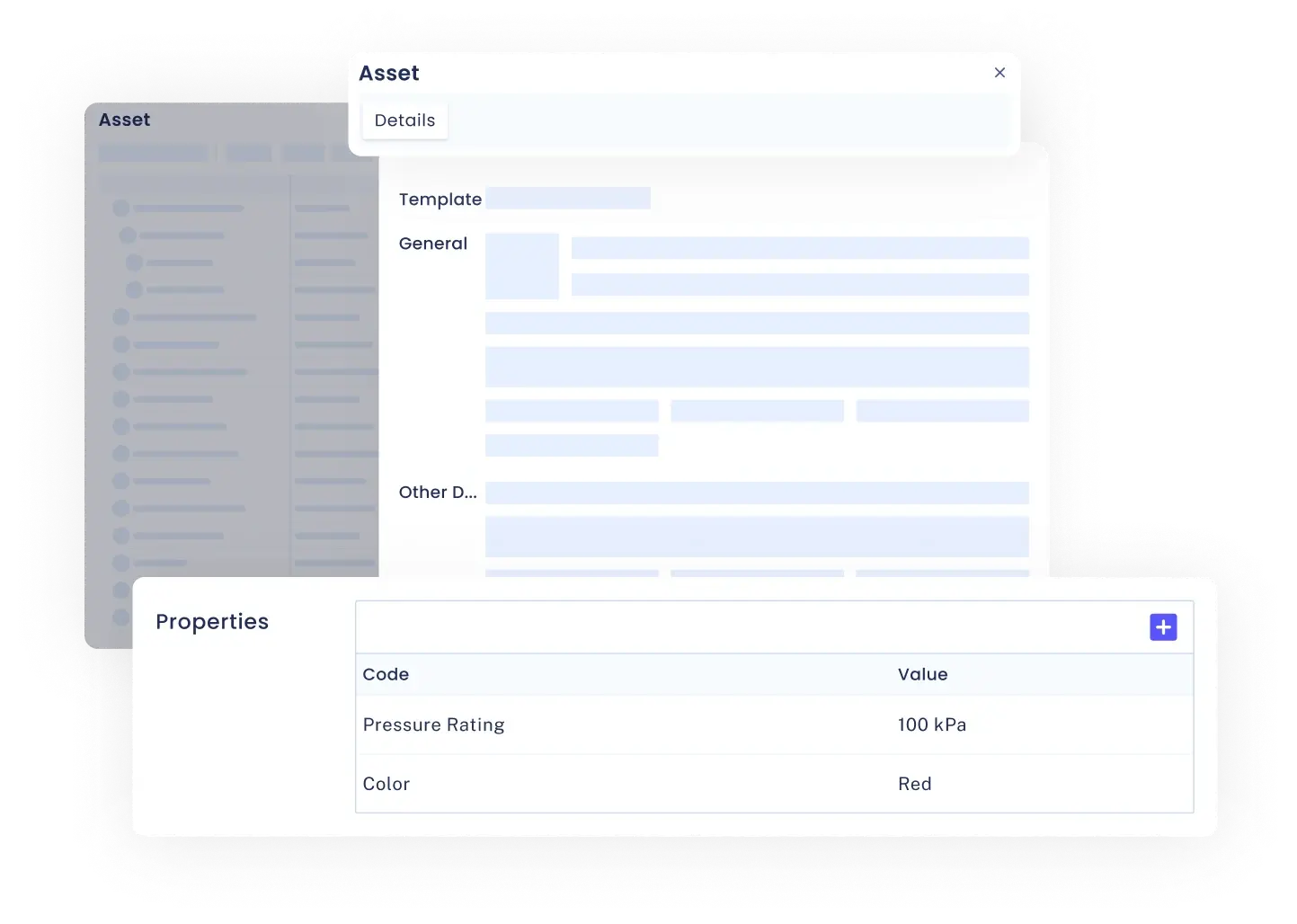

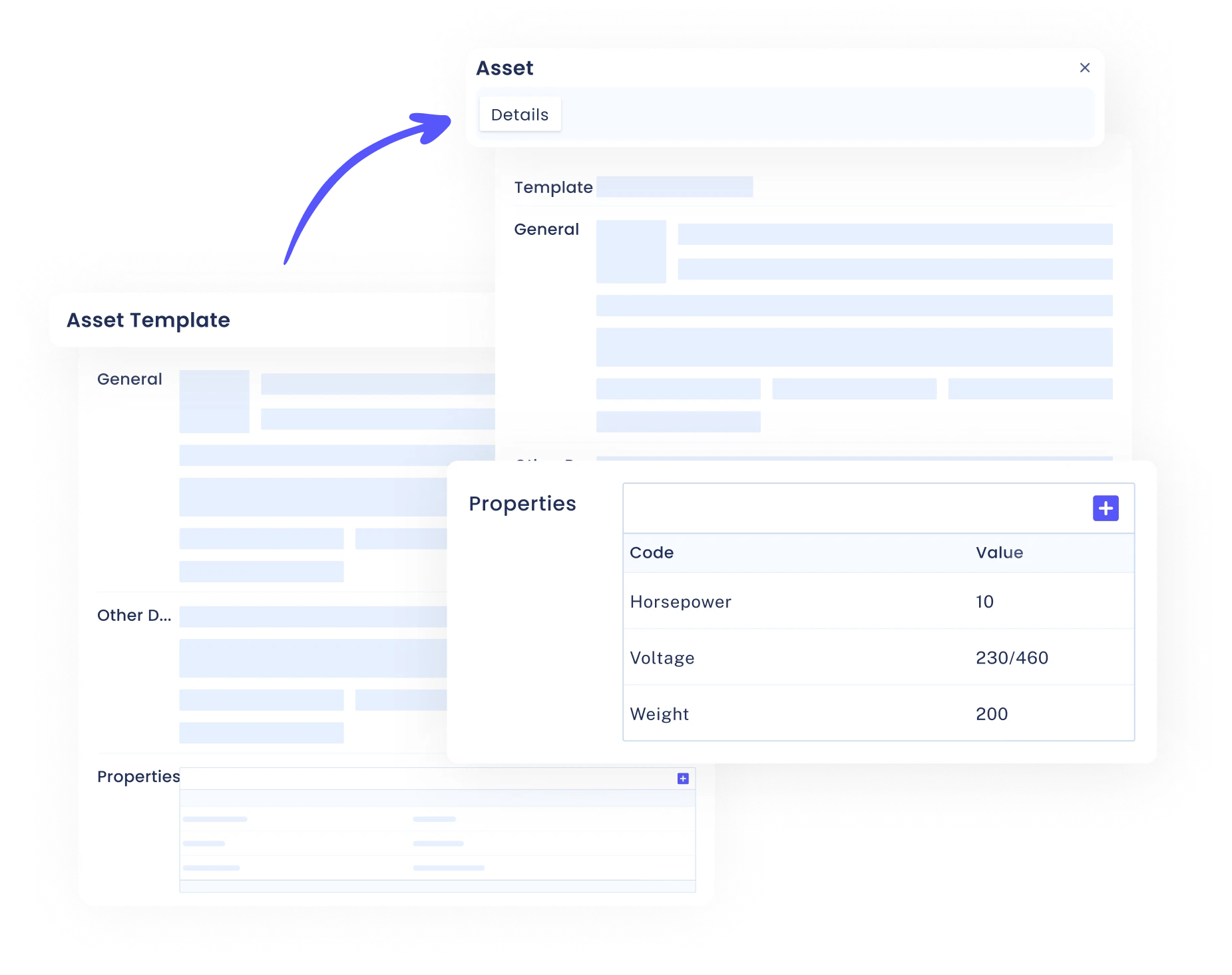

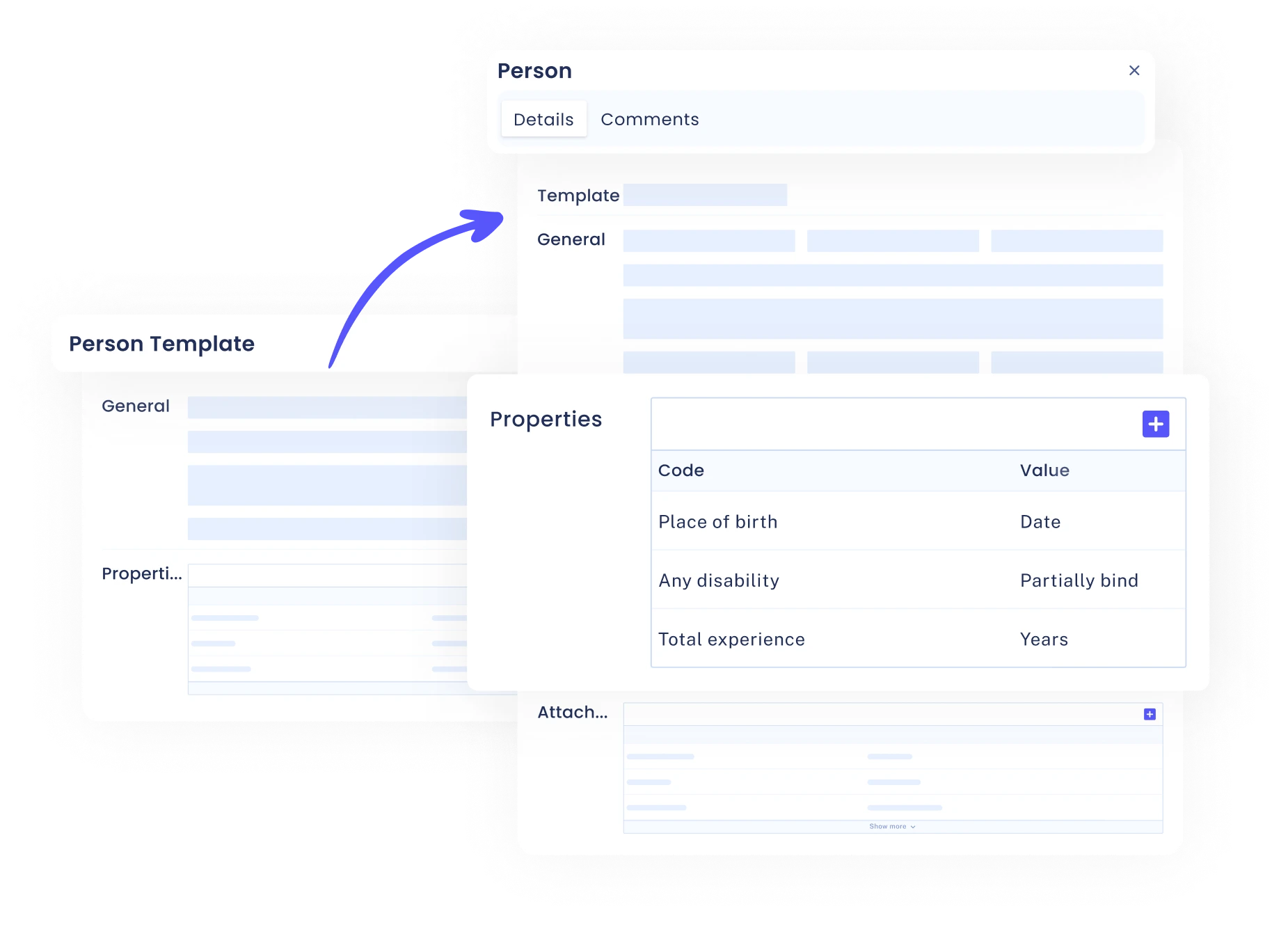

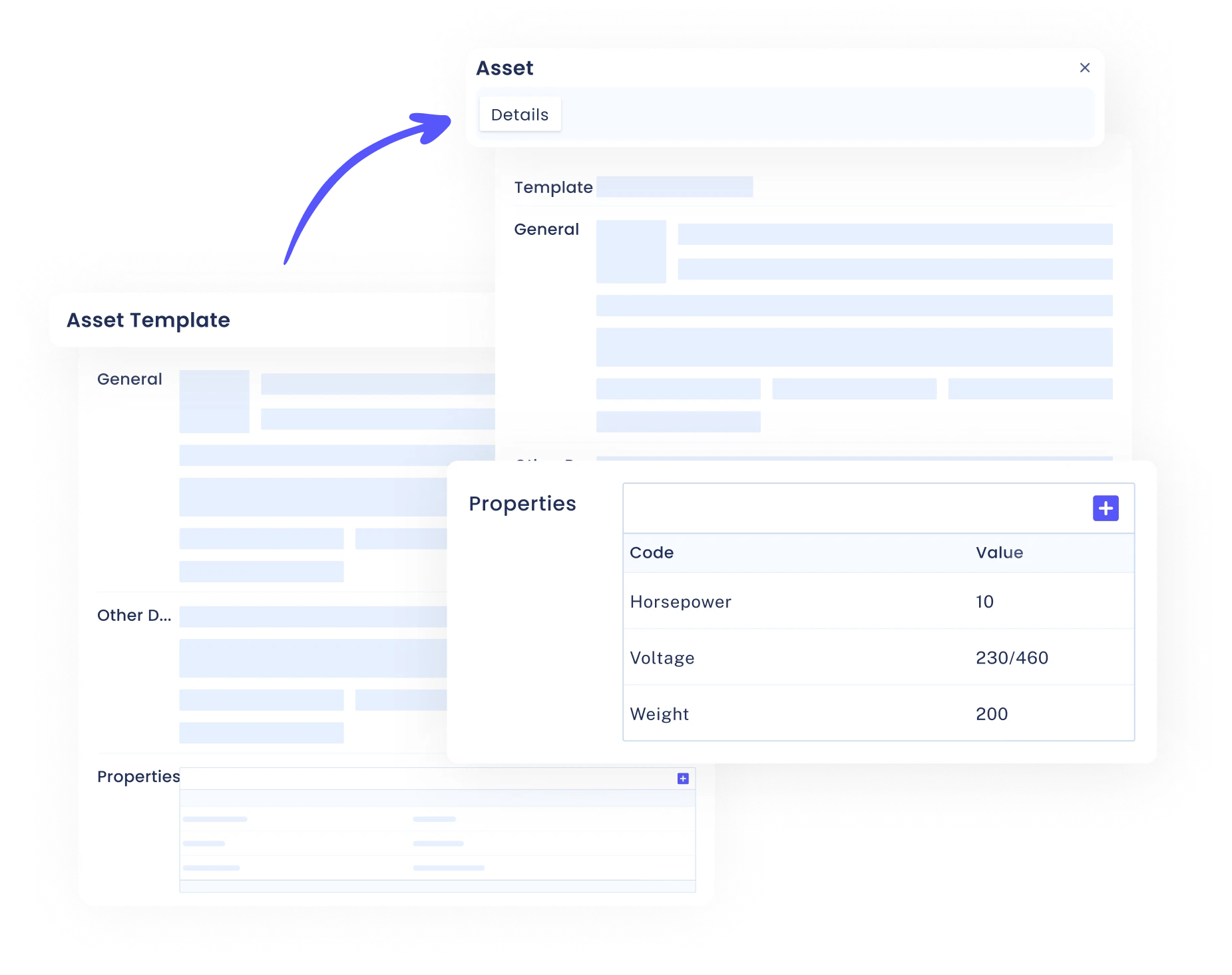

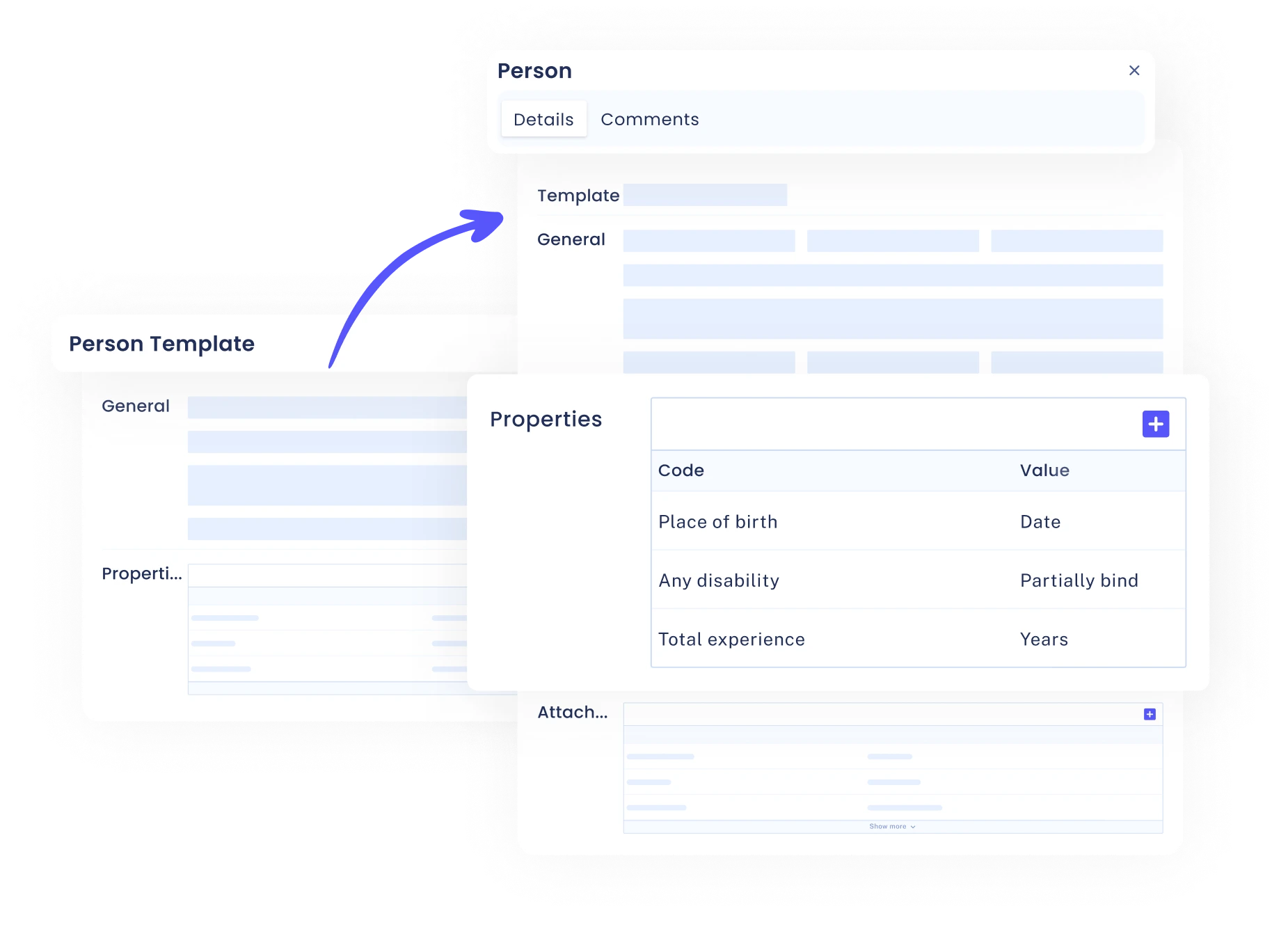

Custom Properties allow you to capture unique information.

Each of Sensys’ Digital Operations Twin concepts can be extended through Custom Properties. This gives you the power to track all the information you need, even if the application doesn’t provide it out of the box.

Examples

- For an Asset - pressure rating, color, weight, build material, etc.

- For a Location - area, operating hours, number of production shifts, etc.

- For a Person - tenure, nationality, years of experience, etc.

- Create custom properties like these for any concept within Sensys.

Save time and enhance reliability

with Templates.

We built Templates to bring efficiency and repeatability to your maintenance operations.

Check out some examples of how it works below.

Features

- Standardised definitions for assets, locations, tasks and work orders to ensure reusability

Features

- Standardised definitions for assets, locations, tasks and work orders to ensure reusability

Digital Operations Twin.