Listen to the Pulse of Your Plant: Asset Lifecycle Management (ALM)

Many factories treat maintenance like an emergency room visit, rushing in only when a machine is flat‑lining. It’s a stressful, expensive, and outdated way to live. During that time, Asset Lifecycle Management (ALM) flips that script.

Instead of waiting for problems to erupt, ALM gives you a full health plan for every asset from the day it arrives to the day it retires. Think of it as preventive care for your industrial heart.

The Price of Living in “Fire‑Fight” Mode

Yes, it’s true – running to failure feels simple. Why fix it if it isn’t broken? Here’s why:

- Unplanned Downtime – Industry studies peg lost production at $10,000 – $250,000 per hour

- Sky‑High Repair Bills – Overtime labor, rush‑ordered parts, and collateral damage send costs through the roof

- Safety Risks and Fines – A seized bearing can snowball into worker injuries and regulatory penalties

- Technician Burnout – Nobody likes being on perpetual 3 a.m. call‑outs

Reactive maintenance is like driving your car until the engine gives up, then paying for a tow, a new block, and a hotel while you’re stranded. Regular oil changes are cheaper every single time.

Unpack Asset Lifecycle Management (ALM): A GPS for Your Assets

ALM is more than a calendar of PMs. It’s a strategic process that balances performance, cost, and risk across the following five clear stages:

1. Planning & Acquisition

Car Analogy – Deciding you need a car, researching models, budgeting, and purchasing

Goal – Ensure the right asset is acquired at the right time and cost

Key Activities

- Demand and performance analysis (capacity, uptime, compliance needs)

- Comprehensive cost–benefit and ROI modelling (CAPEX + OPEX)

- Technology‑obsolescence and supply‑chain risk assessment

- Vendor screening, contract negotiation, and approvals

Risk Lens – Obsolescence, budget over‑runs, mis‑specification, and regulatory gaps.

2. Commissioning & Deployment

Car Analogy – Registration, insurance, and the first test drive

Goal – Verify the asset is safe, compliant, and fully functional before hand‑over

Key Activities

- Installation, calibration, and system integration

- Acceptance testing against vendor guarantees

- Baseline performance data capture

- Operator training and safety certification

Risk Lens – Infant failures, integration conflicts, and documentation gaps.

3. Operations & Maintenance

Car Analogy – Everyday driving and routine servicing

Goal – Sustain safe, efficient operation at the lowest total cost

Key Activities

- Preventive, predictive, and corrective maintenance programmes

- Spare‑parts logistics and supplier coordination

- Continuous compliance and safety monitoring

- Workforce competency management

Risk Lens – Unplanned downtime, safety incidents, and escalating maintenance costs.

4. Performance Monitoring & Optimization

Car Analogy – Using diagnostics and adjusting driving habits to save fuel

Goal – Extend useful life and maximize return on assets in real time

Key Activities

- Live KPI dashboards (availability, MTBF, and energy use)

- Condition‑based maintenance analytics and AI predictions

- Process improvements and control‑loop tuning

- ROI tracking and mid‑life upgrade decisions

Risk Lens – Performance drift, hidden failure modes, and missed improvement opportunities.

5. Decommissioning & Disposal

Car Analogy – Selling, trading in, or responsibly scrapping the vehicle

Goal – Retire assets safely, legally, and economically while preparing replacements

Key Activities

- End‑of‑life inspection and isolation

- Environmental and regulatory compliance (e‑waste and hazardous materials)

- Salvage, refurbishment, resale, or recycling strategies

- Knowledge capture for successor assets

exposure and replacement timing

Risk Lens – Environmental liabilities, residual data/security exposure, and replacement timing.

The Bathtub Curve: Failure Rate Over Time

Stage | Failure‑Rate Trend | Typical Causes | ALM Focus |

Infant Mortality | High, early failures | Design flaws and installation errors | Rigorous commissioning checks and burn‑in testing |

Useful Life | Low, random failures | Normal operational stress | Predictive maintenance and KPI monitoring |

Wear‑Out | Rising failure rate | Material fatigue and obsolescence | Replacement‑planning and life‑extension strategies |

Understanding where an asset sits on the bathtub curve enables data‑driven decisions about maintenance intensity, upgrade timing, and replacement planning – keeping risk and total cost of ownership under control.

Sensys CMMS: Turning Data into Foresight

A philosophy is only as good as the tools that deliver it. Enter Sensys CMMS, the digital nervous system that makes ALM real.

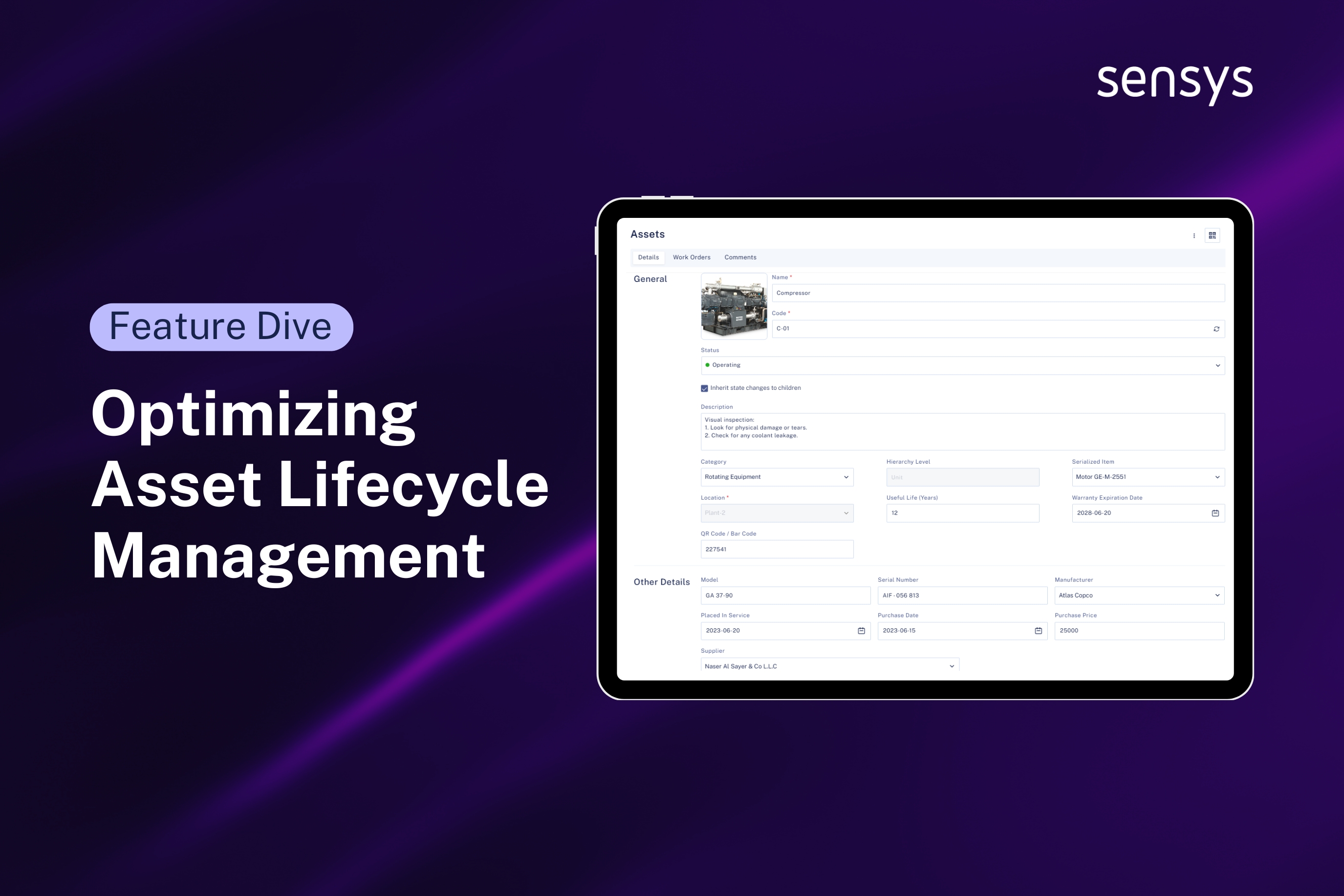

Centralized Asset Registry

Sensys consolidates every critical asset, its location, hierarchy, specs, purchase and warranty details, and full maintenance history into a single digital record. Everyone works from the same, up-to-date information – eliminating silos and speeding decisions.

Use Case – A unit in charge, for instance, can pull up a failed compressor’s history, future PM schedule, and warranty status in seconds, saving time and avoiding unnecessary repairs.

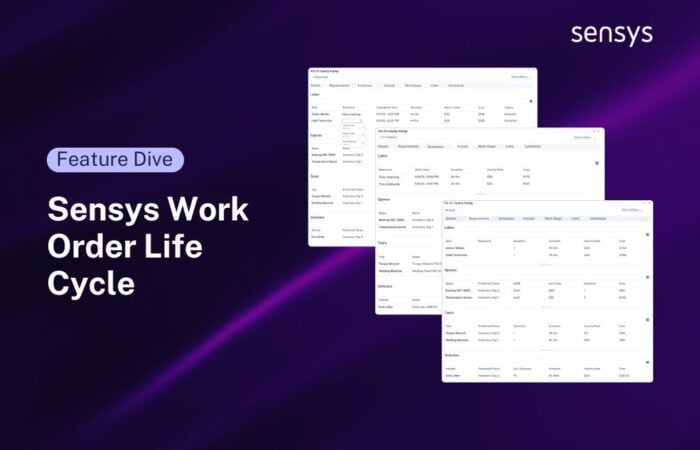

Lifecycle-Linked Maintenance Plans

Our maintenance plan grows with each asset, from commissioning all the way through its busiest days. Sensys reads live data hours on the clock, sensor performance, and manufacturer-recommended checkpoints to pick the best moment for service. That curbs surprise breakdowns, cuts downtime, and avoids wasting time on unnecessary tune-ups.

Use Case – As equipment moves from commissioning into peak workload, Sensys adjusts PM frequencies based on performance data and live usage – preventing both premature failure and wasteful over-maintenance.

Condition Monitoring & Predictive Insights

With plug-and-play sensors and IoT integrations, machines “talk” directly to Sensys.

Use Case – Subtle anomalies like a vibration spike on a motor trigger instant alerts so teams can fix issues days or weeks before a breakdown. This shift from reactive “firefighting” to proactive “fire prevention” slashes downtime and averts catastrophic failures, while laying the groundwork for digital-twin initiatives.

Cost Tracking Over Time

Sensys captures every repair cost, part, labor hour, and downtime loss – giving true total-ownership cost across an asset’s life.

Use Case – When cumulative maintenance on an aging pump reaches, say, 80% of its replacement value, planners have the data to retire and upgrade with confidence, optimizing capital spend.

End-of-Life Decision Support

When retirement looms, Sensys guides orderly decommissioning – managing documentation, environmental compliance, and replacement planning so transitions are smooth and CapEx planning stays informed.

The Payoff: From Cost Center to Competitive Edge

- Improved Up-time – Predictive alerts slash surprise outages

- Costs Down – Fewer break-fix calls, smarter spare-parts buys, and longer asset life

- Compliance Made Easy – Auditors love clean, searchable histories

- Safer Crews, Greener Footprint – Well-tuned machines use less energy and fail less often

- Culture Shift – Teams move from blame games to data-driven problem-solving

But the biggest shift is cultural. When data replaces guesswork, maintenance stops being the department that “fixes what’s broken” and becomes the group that prevents problems in the first place. Technicians feel empowered, planners sleep through the night, and production trusts the schedule.

Don’t Just Maintain Your Assets, Master Their Lifecycle

If you’re tired of firefighting and budget‑busting surprises, it’s time to give your industrial heart a healthier beat. Sensys CMMS equips you with the ALM tools and insights to keep every asset performing at its best today and for years to come.

See Sensys in action. Book a personalized demo or chat with one of our ALM experts. Let’s turn your maintenance program into a competitive advantage and watch your operations thrive.