In a dynamic industrial environment, the smooth operation of any organization can depend on the creation of effective work orders. A work order is a standardized document that outlines the target asset or location, steps, tools, materials, and personnel required for the job. It guides workers to ensure that each task is completed according to the proper standards and within a specified timeline.

In this post, we will cover some of the most important elements in creating work orders that can enable timely and reliable delivery, while laying the foundations for analytics and insights in the future.

Key Elements of an Effective Work Order

- Work Order Title – A descriptive title to help your team understand the task at hand.

- Work Order Number – A unique code for reference and tracking.

- Target Asset or Location – The asset, or which location, on which the work will be performed.

- Priority – The criticality of the work.

- Category – What type of work is it – preventive, corrective, or another type?

- Estimated Time – The expected duration of the work.

- Assignee – The individual responsible for ensuring the work is completed. Note that this can be different from the individual who is scheduled to actually complete the work.

- Tools and Materials – A list of tools or materials, such as spare parts, required to execute the work.

- Work Steps – A set of ordered instructions for how to do the work.

- Safety Instructions – Guidelines to ensure the safety of personnel performing the work.

Creating an Effective Work Order – Important Considerations

Work Order Title and Number

An effective work order has a clear and detailed description of a task and a unique code for tracking. Specifics about the problem, location, and necessary equipment should be included to avoid any vague language. Precise and easy-to-understand terminologies allow technicians to carry out the task efficiently. For instance, “Repair leak in the north section of cooling tower” is more effective than “Fix leak.”

Priority

In managing the workload and dealing with critical problems quickly, assign the right priority level to each job order. For instance, categorizing tasks as “High”, “Medium”, or “Low” based on their impact on the operations will allow the handling of critical repairs swiftly, reducing downtime.

Assignee

Make sure that work orders are assigned to personnel with relevant skills and experience. A person responsible to ensure the task is completed can be different from the one scheduled to complete the task. Using CMMS to track technicians’ competencies and matching them with suitable tasks reduces the likelihood of errors and enhances work quality.

Tools and Materials

List all required materials, tools, and spares needed for the job. This will minimize the delays caused by searching for resources, ensuring technicians can start and complete tasks effectively.

Work Steps

Adding specific instructions or work steps into the work order can dramatically improve technician efficiency and increase the chances of successful completion. While some maintenance tasks may be too complicated or uncertain to capture in detailed instructions, most maintenance activities involve repetitive steps that should be followed to ensure success.

Safety Instructions

Include detailed safety instructions that all personnel are aware of and comply with safety standards. This will prevent injuries and accidents. These safety -instructions may even be combined with work steps so that field personnel formally complete safety “checklists” prior to commencing maintenance activity.

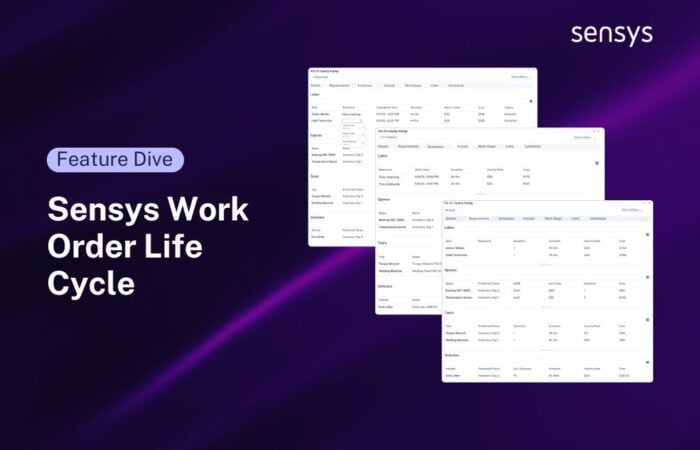

At Sensys, we believe that creating effective work orders is one of the pillars of an effective maintenance practice. Our Work Order module offers a rich set of features that will allow you to capture all of the information listed in this article, and more.

If you’d like to learn more, get in touch for a free demo!