Work order management, which seems like a simple task, can cost you millions if done poorly. For instance, a routine bearing replacement, typically a 4-hour job, can be stretched into a 3-day shutdown halting production.

The culprit? Not equipment failure. Not technician error. Poor work order planning.

The bearing was in stock, but at the wrong warehouse. The serialized tool was being used on another job. The experienced technician was scheduled for vacation. And nobody discovered these conflicts until the equipment was already down.

Most maintenance teams are all too familiar with this nagging feeling, that sense of unease when small issues start to pile up. Yet they often let it slide, hoping things will somehow resolve themselves. But what begins as minor concerns gradually snowballs into chaos on the floor, and by the time the situation gets completely out of control, senior management finds themselves pulled into the fray, demanding answers and immediate action.

Now think of your best maintenance day ever, the one where everything just clicked. The right technician showed up with the exact parts needed, tools were waiting where they should be, and the job finished ahead of schedule. That wasn’t luck. That was orchestration.

At Sensys, we’ve spent years studying what separates maintenance operations that consistently hit their marks from those that constantly scramble to catch up. The answer isn’t better technicians or fancier tools; it’s intelligent orchestration of every moving piece through our Advanced Planning and Scheduling framework.

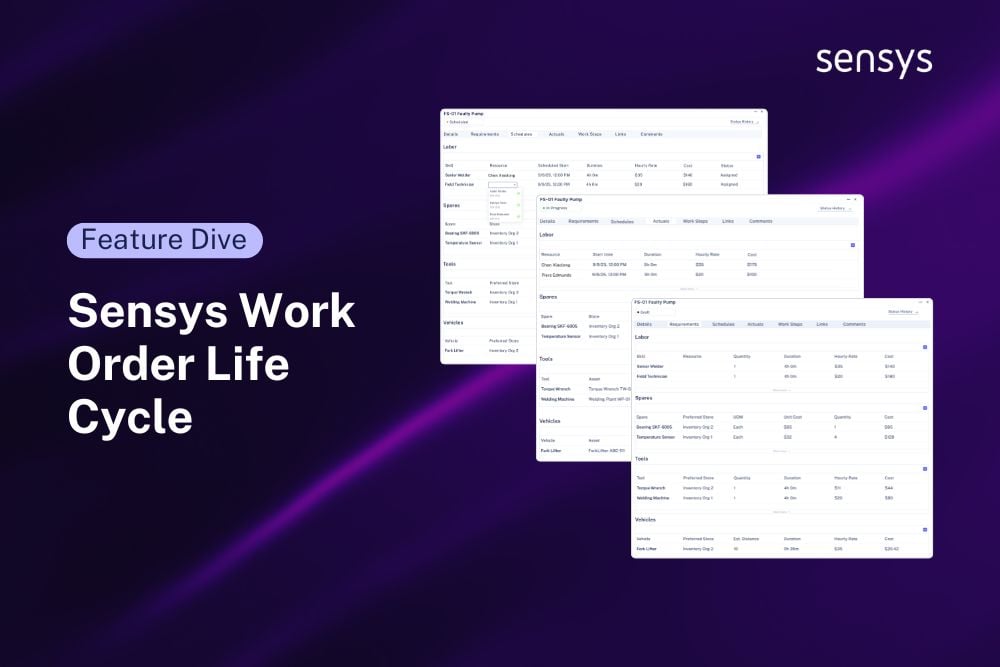

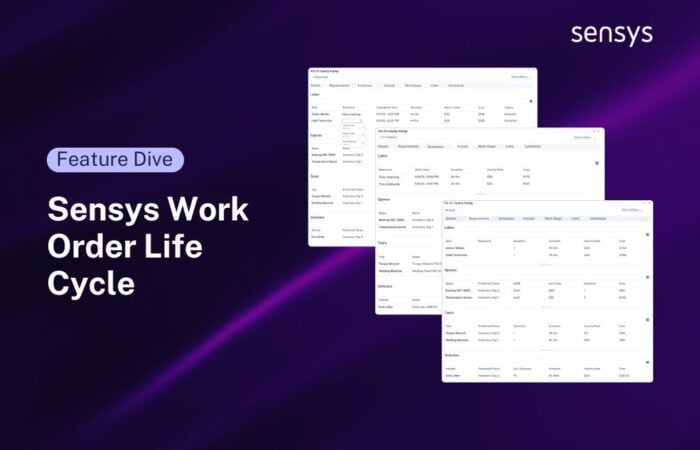

In this feature dive, we’ll walk you through the three phases of the Sensys Work Order Life Cycle:

1. Planning Phase – Defining What’s Needed

The first step in any maintenance task is clear definition: what exactly is required to get the job done?

In Sensys, this responsibility lies with the Area or Maintenance Engineer, who ensures every resource, whether people, spares, or equipment, is identified before work begins.

Labor Planning

With Sensys, you can plan labor in two flexible ways:

- Skill-based assignment: Keep things open-ended by specifying the skill (e.g., “Certified Welder”) if you don’t yet know who will do the job.

- Person-based or team-based assignment: Assign the exact technician or crew when you know who is available.

Example: A shutdown maintenance task may require “2 welders” (skill-based). Later, you can assign John and Ahmed from the welding team (person-based).

Spare Parts Planning

Unplanned spare shortages are a planner’s nightmare. With Sensys, you can:

- Define the exact spare parts (e.g., “Bearing 6205, qty: 4”).

- Set the preferred store or warehouse to source from.

This proactive approach ensures critical components are ready when needed with no last-minute surprises or delays.

Tools Planning

Whether it’s a general tool (e.g., Welding Machine) or a specific serialized tool (e.g., Welding Machine WD-100), Sensys lets you plan at the right level. This flexibility allows for precise tool traceability, along with setting preferred store, linked asset, quantity, and estimated usage duration.

Vehicle Planning

Vehicles can be planned just like tools. You can choose:

- A general type (e.g., Forklift), or

- A specific serialized vehicle (e.g., Forklift FL-101).

This ensures flexibility while keeping control of utilization, travel distance, and operating hours.

2. Scheduling Phase – Turning Requirements into Reality

Once all requirements are captured, it’s the Planning Engineer’s turn to schedule them into action. Sensys makes this simple with a powerful scheduling engine that supports automatic, manual, or hybrid scheduling.

Labor Scheduling

The labor scheduling can be generated automatically based on the requirements or the Planning Engineer can assign specific individuals or teams to perform the task at a designated time. Sensys ensures only those with the required skills are eligible for assignment.

Spare Scheduling

Planned spares can be automatically scheduled, and reservations are created in the inventory. This means the right part is physically allocated and ready to go when the job starts.

Tool & Vehicle Scheduling

Tools and vehicles, whether general or serialized, are scheduled against specific time slots and travel requirements (in case of vehicles) ensuring no conflicts or double bookings.

At a glance: Planning Engineers can view dashboards showing workload, conflicts, and capacity availability, helping avoid bottlenecks and improving overall resource utilization.

3. Execution Phase – Recording Actuals for Continuous Improvement

Even the best-laid plans need real-time adjustments. In this phase, Supervisors and Technicians record what really happened: the actuals. This allows organizations to track performance, compare plans vs. execution, and improve continuously.

Labor Actuals

Track real working hours versus planned hours. If extra manpower was required or more time was spent, this gets logged to improve accuracy in future planning.

Spare Actuals

Technicians log the actual inventory consumed. Whether substitutions were made or usage differed from the plan, Sensys updates inventory balances in real-time, ensuring accuracy and cost control.

Tool Actuals

Capture which specific tools were used, for how long, and in what condition. This helps in monitoring high-value or calibration-sensitive equipment.

Vehicle Actuals

If vehicles like forklifts or service trucks were used, details such as vehicle ID, hours, and distance traveled are recorded. This provides visibility into vehicle workload and maintenance needs.

Why Sensys Stands Out

Here’s what makes Sensys CMMS Work Order Life Cycle different from other solutions:

Feature | Sensys Advantage |

Skill-based + Person-based + Team-based Planning | ✅ Flexibility + Precision |

General & Serialized Tools & Vehicle Assignment | ✅ Full control |

Reservation Mechanism from Work Order | ✅ Zero delays |

Plan–Schedule–Actual Tracking | ✅ Closed-loop monitoring |

Persona-Based Role Clarity (Engineer, Planner, Technician) | ✅ Clear accountability |

Industries like Oil & Gas, Utilities, Manufacturing, and Large-Scale Facilities can’t afford downtime or resource misallocation. Sensys provides the end-to-end visibility that transforms maintenance from a reactive burden into a predictable, data-driven advantage.

Conclusion

In an era where uptime is everything, Sensys CMMS empowers organizations to always stay ahead:

- The right people, with

- The right parts, and

- The right plan.

If you’re managing complex operations and feel limited by your current CMMS, it’s time to experience what true Advanced Planning and Scheduling feel like, with Sensys.

Ready to see how Sensys can transform your maintenance operations? Get in touch with us today.